- Screen Colours:

- Normal

- Black & Yellow

This article was ‘…sparked by a walk along the shore between Lower Holbrook and Harkstead, where Google Maps shows a stretch marked "Copperas Reach". (There is now a modern £1m+ house of the same name on the lane from the shore back up to Harkstead). Apparently it was the practice of the wives and children of local sailors (bargees, I assume, rather than the Royal Navy) to go beach-combing for mineral Copperas. How it was transported from beach to processing works is another unanswered question, but my guess is by a small boat as far as possible.’ ‘Another thing that piqued my initial curiosity was a brief mention in the book Balls and rollers: a history of printing ink 1440-1850 by one C.H. Bloy (1967). The things one finds in charity bookshops!’ (James Meek)

This article was ‘…sparked by a walk along the shore between Lower Holbrook and Harkstead, where Google Maps shows a stretch marked "Copperas Reach". (There is now a modern £1m+ house of the same name on the lane from the shore back up to Harkstead). Apparently it was the practice of the wives and children of local sailors (bargees, I assume, rather than the Royal Navy) to go beach-combing for mineral Copperas. How it was transported from beach to processing works is another unanswered question, but my guess is by a small boat as far as possible.’ ‘Another thing that piqued my initial curiosity was a brief mention in the book Balls and rollers: a history of printing ink 1440-1850 by one C.H. Bloy (1967). The things one finds in charity bookshops!’ (James Meek)

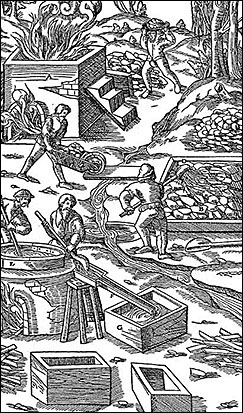

Left: Copperas production in the 16th century

Left: Copperas production in the 16th century

Copperas is an old name for green iron-sulphate crystals, also known as Iron pyrites, or ‘Fools gold’ because it was sometimes mistaken by prospectors for gold. (Derivation: Middle English - Coperose; Old French - Couperose. Medieval Latin - cuprosa / cuperose; origin: aqua cuprosa - copper water). John Norman found two Copperas Woods, one in Essex and one near Campsea Ashe – were these the sites of the source mineral? This mineral was apparently used in industrial processes in Ipswich (possibly in Victorian times). So who used it, and where?

Dr John Warren (JW), the Chairman of the River Gipping Trust which contributes to the restoration of the river, was able to provide most of the information which follows.

Brightlingsea has a similar history, well-researched here: https://morganmarine.com/news-events/copperas-a-small-bit-of-history. There are plenty of ‘copperas’ names on Suffolk and Essex maritime charts.

So, a medieval resource taking Fool’s Gold to make sulphates for a variety processes. The coprolite industry may initially have used this as a source of sulphuric acid. This was added to the coprolite to release phosphate, eventually used as an agricultural fertiliser. Incidentally, later manufacture of sulphuric acid generated much arsenic as an unwanted by-product. This contamination is one reason why the abandoned factory site at Paper Mill Lane, Bramford – once the Packard and Fisons works – is a challenge to developers. JW thinks that the Packard barges used to take jars of sulphuric acid up to Bramford and had to be careful that the kids on the bridges did not break the jars by throwing stones.

There is some text in the Stowmarket Food Museum. It describes Prentices, Packards, and Fisons each manufacturing sulphuric acid in the 1840s and 1850s to make superphosphate fertilizer. All three companies built a factory alongside the navigable Gipping above Bramford, adjacent to each other – fewer neighbours to complain about the pollution; the companies eventually amalgamated.

From https://www.cumbria-industries.org.uk/a-z-of-industries/chemicals:-

The manufacture of copperas held a key position in the early chemical industry from the 17th century, but especially from the mid-18th to the mid-19th centuries. Copperas had nothing to do with copper, but was made from iron pyrites (alternatively referred to as ‘fool’s gold’, ‘marcasites’ or ‘brass lumps’) mainly found in coal measures.

The manufacturing process involved laying small pieces of pyrites to a depth of two feet in a tank, which was left open to the elements to “ripen” for 4 or 5 years. The liquor that was produced was collected in a cistern, boiled and cooled, with the addition of amounts of scrap iron to control its strength. Crystals of copperas,“green vitriol”, formed on twigs and branches suspended in the liquor, and were used to produce ink or black dyes (or to darken other dyes). The remaining liquor would be heated to produce “oil of vitriol” i.e. concentrated sulphuric acid, and the residue of red iron oxide used in pigments for the paint trade. The “oil of vitriol” was used to prepare Epsom salt from magnesian limestone – for medicinal purposes or as a mordant in dyeing – or with alum as another mordant.

The Carlisle Journal of 1st January 1820 includes the following sale notice:

‘A well established works occupying 3 acres and having a long range of buildings, mostly cellared, containing 1 lead boiler which contains 5 to 6000 gallons, 4 coolers, 3 of which are lined with lead, several lead pumps (which are well supplied with water) and troughs and all other necessary fixtures and fittings. The cellars are flagged and walled round with freestone and bricks for the reception of copperas liquor to which belong the extensive beds or brass lumps near the same. There is no other copperas works in the County… A sufficient quantity of brass lumps may be obtained from the collieries at Whitehaven from which copperas may be conveniently exported.’

This was the works established by Sir John Lowther in The Ginns at Whitehaven in 1718 and referred to in R.R. Angerstein’s illustrated travel diary of 1753-1755 as the “vitriol works at Whitehaven” with this description:

‘The iron pyrites, which is found in the coal here, is sold to the vitriol works situated near Whitehaven. The price is the same as that for coal, 3s 4d per ton. The pyrites is laid out in rows on a piece of ground that has been walled in. The vitriol is leached out gradually, depending on how much rain falls, and is led to a cistern. From here it is pumped up into the lead vessel where iron scrap is added in a certain proportion… In this way 3 tons of vitriol can be boiled here per week, for which ½ ton of scrap iron is used. The vitriol is sold to Ireland for £9 per ton.The scrap iron comes from Holland, is bought in London packed in barrels and consists of old nails, locks, keys and all kinds of rusty iron.’

Rowell Bell suggests that the processing of copperas wasn’t confined to Victorian industrialised Ipswich, but goes back a lot further. He points to ancient processes such a those carried out in tanneries – a trade with a centuries-old presence in Ipswich. Incidentally, James Meek has also made the link to the production of printer’s ink.

R.G. Thanks to the contributors.

Notes

Prentice Brothers. Prentice’s Gun Cotton Works, of Stowmarket.

1856: business founded.

1891: the company was registered on 4 August, to acquire the business of chemical manufacturers of the firm of the same name.

1929: in response to deterioration in the business climate, Packard and James Fison (Thetford) Limited amalgamated with two East Anglian competitors, Joseph Fison and Co and Prentice Brothers; the resultant company was named Fison, Packard and Prentice Ltd. [Information from Grace’s guide.]