- Screen Colours:

- Normal

- Black & Yellow

The most recent addition to our Image Archive is the Vickers-Petters Album. Pat and David Rogers kindly donated the physical photograph album, found in their loft, originally saved by Pat's grandfather R.W. Reed, who worked in the publicity department of the company. The album, which will eventually find its way into the county archive in The Hold is a bit battered, barely keeping its pages together, but contains some of the most striking images of early twentieth century industry that we have ever seen.

The most recent addition to our Image Archive is the Vickers-Petters Album. Pat and David Rogers kindly donated the physical photograph album, found in their loft, originally saved by Pat's grandfather R.W. Reed, who worked in the publicity department of the company. The album, which will eventually find its way into the county archive in The Hold is a bit battered, barely keeping its pages together, but contains some of the most striking images of early twentieth century industry that we have ever seen.

The company, just off the Hadleigh Road, produced ‘oil engines’ (diesel engines) from 1913 to 1928. There had been a complex and tortuous history of amalgamation and take-overs leading to the formation in 1921 of Vickers-Petters Ltd.

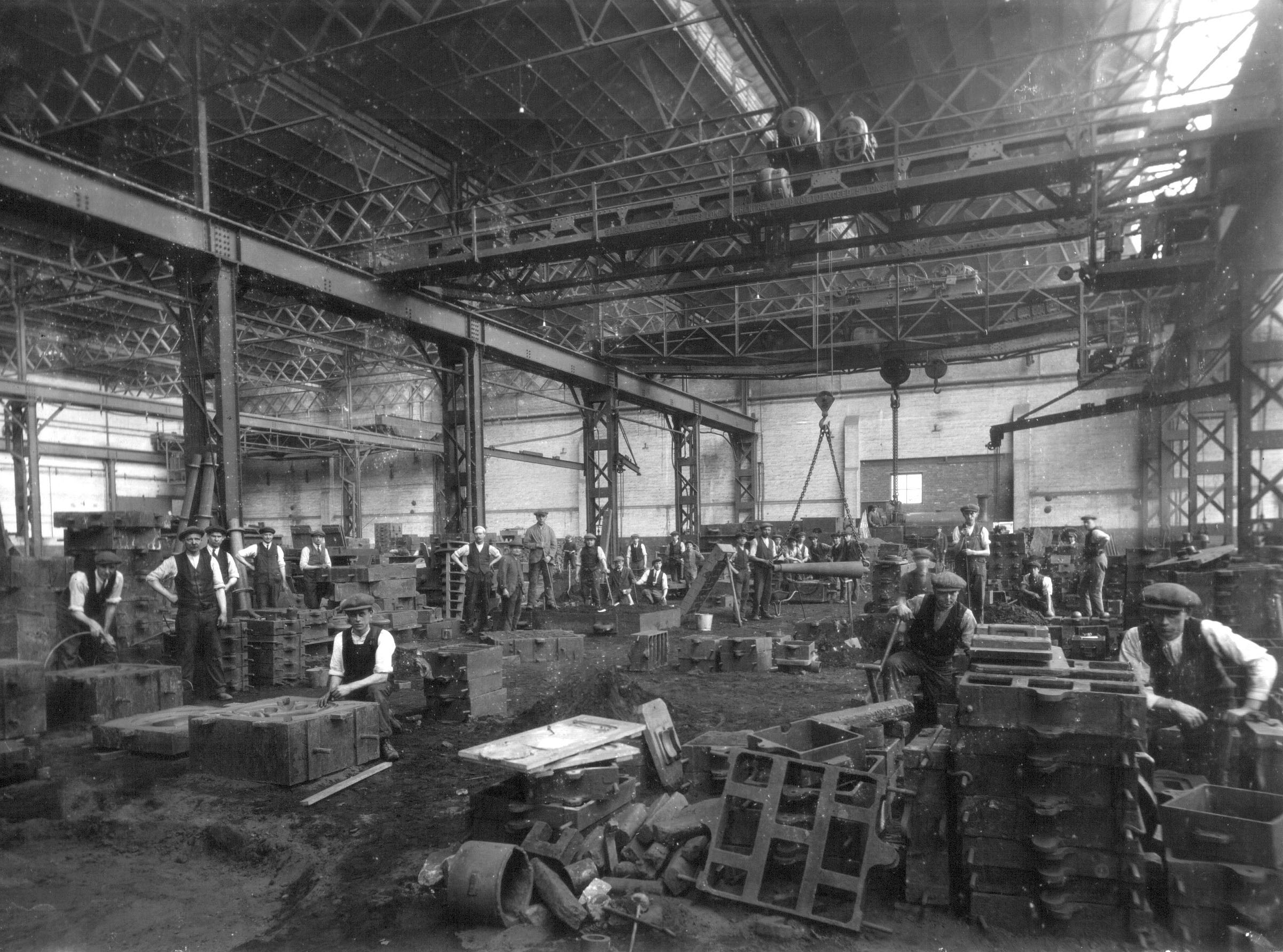

Above: a bay in Vickers-Petters Foundry

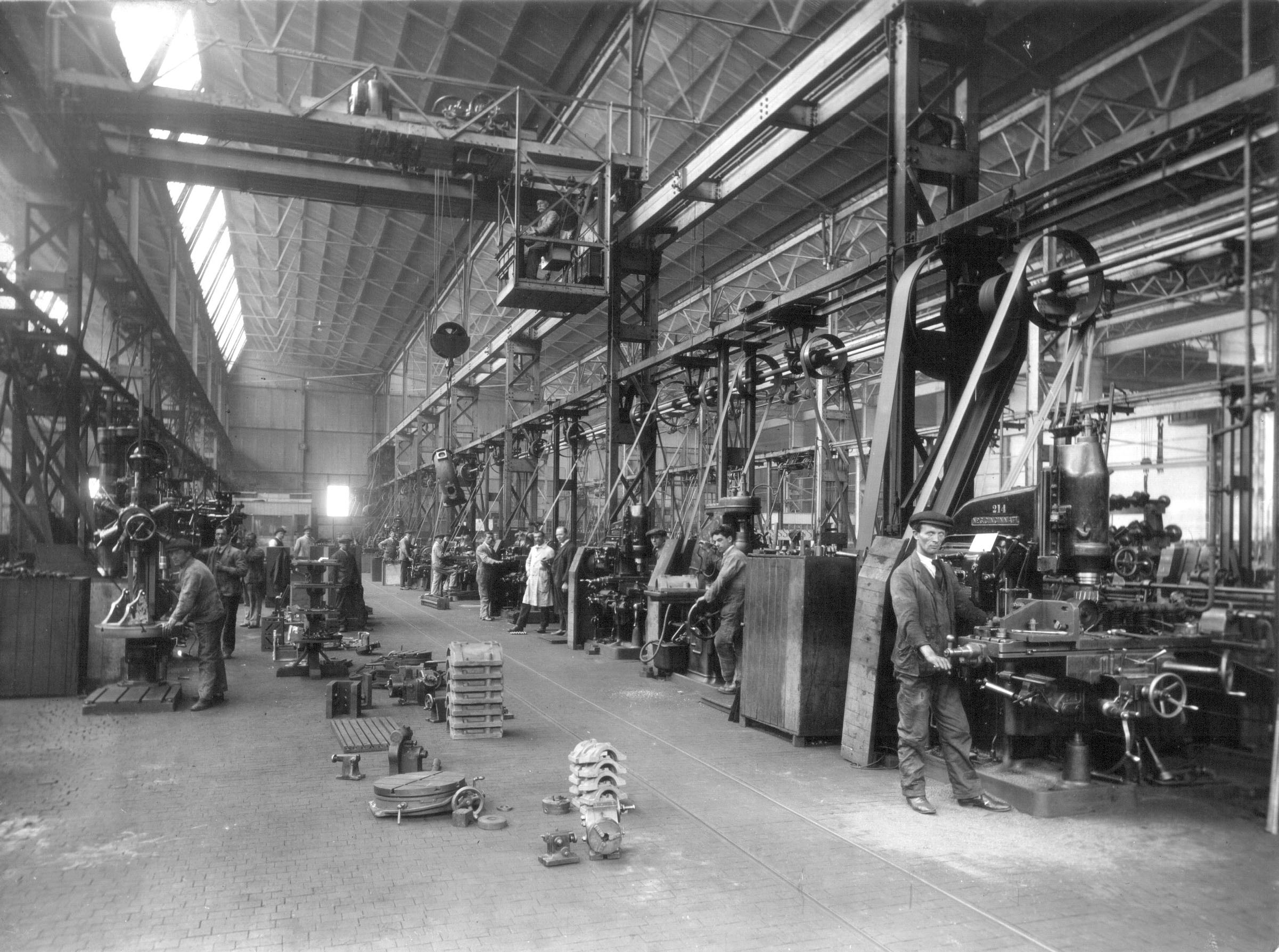

The site of the works was about forty-six acres, the actual workshops occupying about a quarter of that and it is possible to see, from photographs and images, the vast size of the factory. It is also evident from the photographs that the work force was also huge and probably almost all wore flat caps, with another large majority wearing waistcoats – in the factory! There are a few boiler suits in evidence.

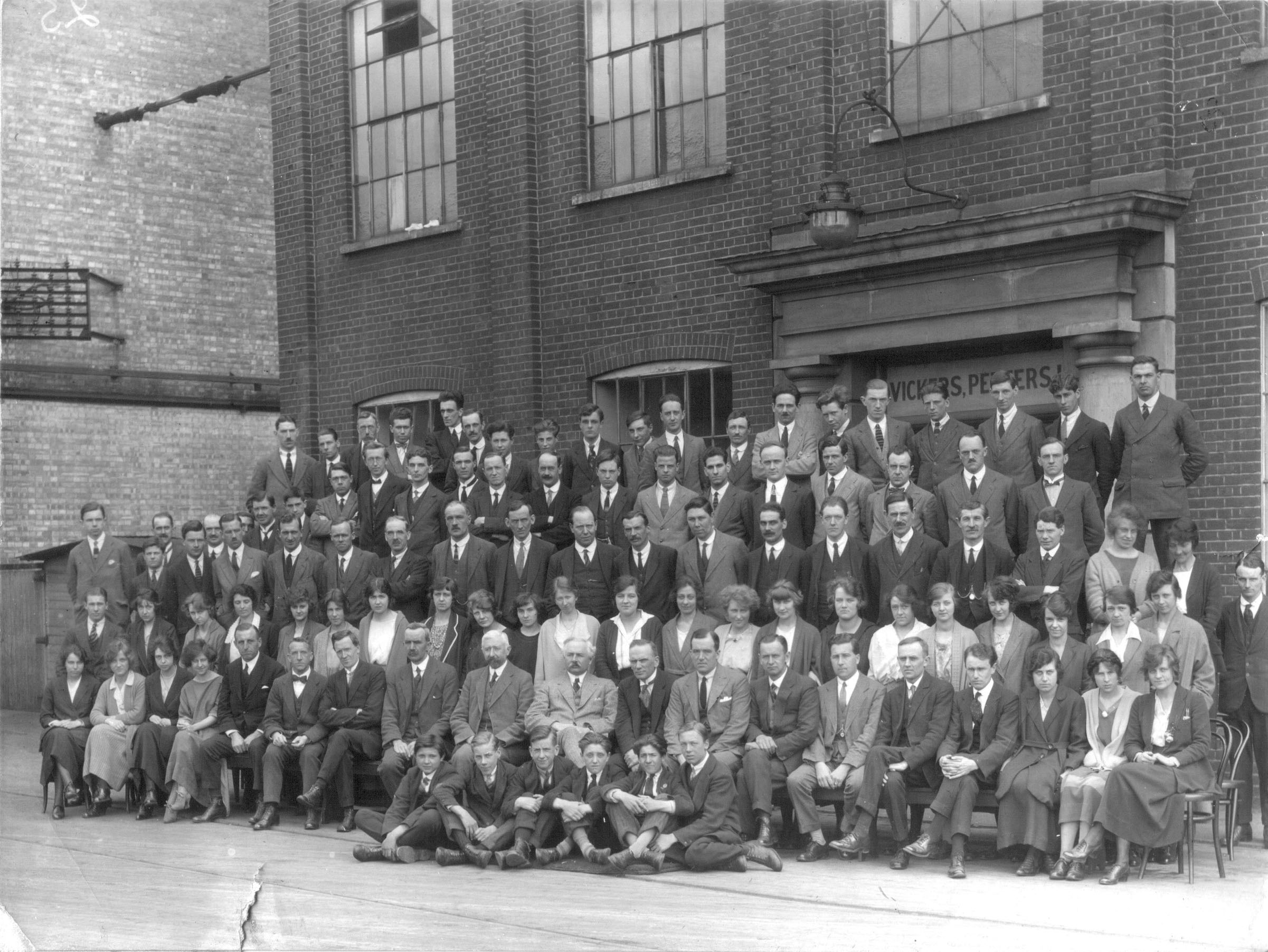

One instructive staff photograph (shown above) sees the ‘staff’ posing outside the offices of the company, all 105 of them. The women seem tucked away at each side with all those men (some in wing-collared shirts); one assumes that they were tracers and typists. The twenties fashions, hairstyles and moustaches are fascinating. Mary Pickford and John Barrymore were on at the flicks and the twenties were roaring... and perhaps so in Ipswich?

Handily, there is an outline guide to the identities of the staff in the photograph from the Managing Director Mr E.W. Petter to the lowliest print room boy Dewhurst who sits at his feet along with the other five ‘boys’ employed in the various offices.

The full process from pattern making via a Jolt Ramming Machine to foundry work, fettling, heavy and light machining to finishing, is illustrated with a clarity and detail which leaves us in no doubt how arduous, yet intricate was the production of the engines.

Above: Vickers-Petters Light Machine shop bay.

Looming weighty objects hang overhead in the control of the crane operators in strange cages at roof level – and how dangerous were those drive belts, spinning at speed above the operatives’ heads? There is a worrying lack of protective equipment.

However, the predominant impression given by the posing workforce in their workplaces is of a busy and successful company. So one wonders how Ipswich managed to lose such an important asset (and employer), and how Petters could effectively write off all of the infrastructure: where did all the lathes, milling machines and toolmaking equipment go?

With the muck and toil of the foundry, the relative calm and ease of the pattern shop and the regimentation and formality of the group photograph, this is a full and fascinating account of the short duration in our town of a significant company. See it now at:

https://www.flickr.com/photos/ipsoc/albums/72157717916218297

Tony Marsden